Nylon Custom 3D Printing Material for Durable Prototyping

Introduction to Custom Nylon 3D Printing and High-Durability Prototyping

Custom nylon 3D printing material is an essential resource for creating strong, resilient prototypes used in demanding applications. Known for its impressive mechanical properties—including flexibility, impact resistance, and heat tolerance—nylon is the preferred choice for engineers, designers, and manufacturers aiming to produce durable, functional prototypes. Whether you’re testing mechanical performance or preparing low-volume production runs, nylon material ensures both strength and precision.

The Craft of Durable Nylon Prototyping with 3D Printing

What Makes This Material Unique?

Nylon stands apart due to its engineering-grade toughness and excellent surface finish. When custom-printed, it adapts to complex geometries and delivers high-quality detail suitable for both visual models and load-bearing parts. Its excellent fatigue resistance and wear tolerance make it ideal for hinges, enclosures, gears, and other moving components. Nylon’s compatibility with SLS (Selective Laser Sintering) and MJF (Multi Jet Fusion) technologies ensures maximum performance and design freedom.

The Strength and Flexibility of Nylon 3D Printing

Custom nylon prints offer a remarkable balance of rigidity and flexibility, which makes them suitable for both structural applications and dynamic movements. Whether in aerospace, robotics, automotive, or consumer electronics, nylon prototypes consistently perform under pressure. The low friction coefficient also makes it ideal for mechanical testing and functional design evaluation.

Benefits of Custom Nylon 3D Printing Material

Optimized for Functional Prototyping and End-Use Applications

This material allows users to print lightweight yet high-strength parts. It supports precision engineering, threaded inserts, and snap-fit designs. The parts are heat-resistant, abrasion-proof, and dimensionally stable, making them reliable under real-world conditions. The natural white or black finish can be post-processed, dyed, or polished for visual enhancement.

Cost-Efficient and Production-Ready

Custom nylon prints reduce the need for tooling, enabling rapid iterations and short-run production with minimal cost. Their high repeatability and excellent chemical resistance make them suitable for industrial workflows and lab testing environments.

Application Versatility Across Industries

From consumer goods to medical devices and machine parts, nylon prototypes cater to a wide range of prototyping needs. This material is especially useful for:

-

Gear and bearing housings

-

Functional enclosures

-

Wear-resistant hinges

-

Clip and snap-fit designs

-

Concept models for rugged field tests

With its combination of toughness and flexibility, custom nylon 3D printing is trusted by professionals seeking dependable results with design freedom.

| All-Powerful 3D Printing, Supporting Any Product Customization | |

|---|---|

| Quotation | Contact Us to Get a Quotation Within 24 Hours |

| Our Lead Times | Sample: 5 Days, Mass Production: 2 Weeks |

| Product Name | Custom 3D Printing Material |

| Type | 3D Printed Items |

| Material | Nylon |

| Feature | Breathable |

| Season | All-season |

| Colors | Customizable |

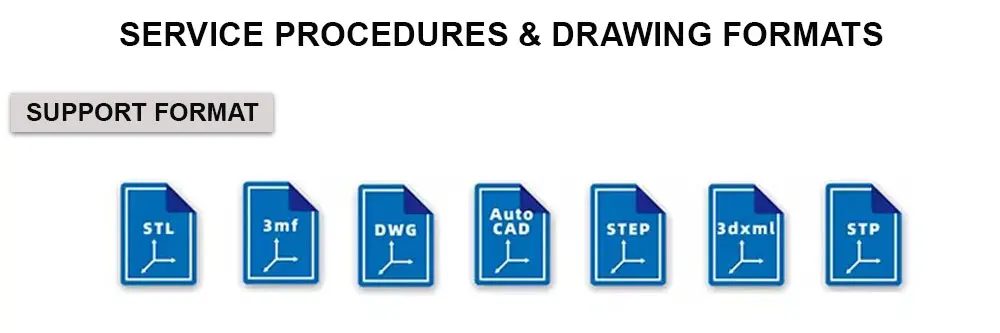

| Drawing Formats | X_T, JPG, PDF, DXF, DWG, IGS, STP, STEP, STL, etc. |

Customization Options

Color (Min. order: 1,000 pieces)

Customized logo (Min. order: 1,000 pieces)

Customized packaging (Min. order: 1,000 pieces)

Graphic customization (Min. order: 1,000 pieces)