3D Print Nylon Dyed Prototyping Plastic 3D Printing Supplier

Introduction to Nylon Dyed Plastic Prototypes and High-Quality 3D Printing

3D printed nylon dyed prototypes combine industrial-grade strength with vivid coloring, ideal for functional prototyping and production-ready parts. As one of the most reliable and versatile materials in 3D printing, nylon (PA12/PA6) offers high impact resistance, flexibility, and thermal stability. When dyed, these prototypes take on an aesthetic finish perfect for visual presentations and product testing. This service is widely used across industries from automotive and aerospace to consumer products and electronics.

The Craft of Nylon Dyed 3D Plastic Prototypes

What Makes These Prototypes Unique?

Unlike ordinary PLA or ABS models, dyed nylon prototypes offer engineering-grade mechanical performance along with customizable visual appeal. The nylon material is durable, wear-resistant, and well-suited for complex geometries or snap-fit applications. Post-processing with industrial dyes ensures deep color saturation, UV-resistance, and a professional matte finish—making these prototypes both functional and visually appealing.

The Beauty of Strength and Design Versatility

These dyed nylon parts are printed with precision using advanced technologies like SLS (Selective Laser Sintering) or MJF (Multi Jet Fusion), enabling detailed, high-resolution parts with exceptional strength-to-weight ratio. Whether you’re prototyping mechanical components or end-use parts, this process ensures the prototype performs and looks like a finished product.

Benefits of Nylon Dyed Plastic 3D Printing

Ideal for Functional Testing, Visual Prototypes, and Low-Volume Production

These nylon dyed prints are not just for display—they’re tested in real-world use. Perfect for engineering validation, design iterations, and customer demos, they offer excellent fatigue resistance and dimensional accuracy. Dyeing enhances appearance without compromising part quality or performance.

Perfect Balance of Performance and Appearance

Nylon dyed parts are valued for their vibrant look, toughness, and precision. They’re widely used by design engineers and product developers who need reliable prototypes that can handle stress while being visually striking. Whether matte black, blue, red, or custom shades, dyed nylon parts give you full control over branding and presentation.

Professional-Grade Prototyping for Every Industry

From robotic arms to footwear molds and electronics housing, nylon dyed parts adapt across industries. They support threaded inserts, living hinges, complex mechanisms, and interlocking parts. With surface treatments like vapor smoothing and dye finishing, each piece is tailored for peak performance and aesthetics.

| All-Powerful 3D Printing, Supporting Any Product Customization | |

|---|---|

| Quotation | Contact Us to Get a Quotation Within 24 Hours |

| Our Lead Times | Sample: 5 Days, Mass Production: 2 Weeks |

| Product Name | Best Shoes 3d Printing Manufacturers |

| Type | 3D Printed Items |

| Material | Nylon |

| Feature | Breathable |

| Season | All-season |

| Colors | Customizable |

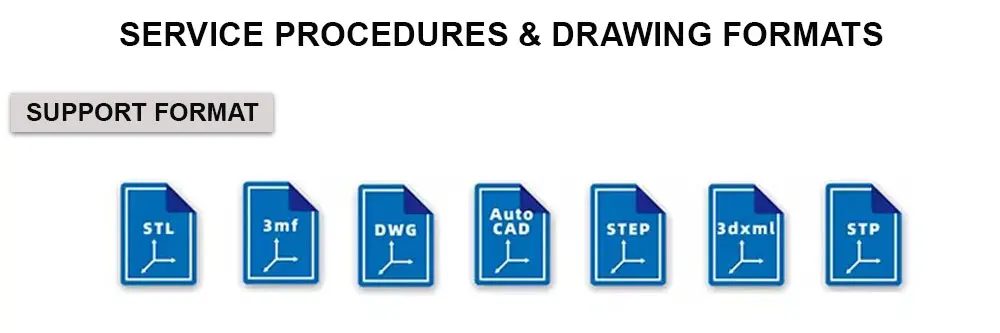

| Drawing Formats | X_T, JPG, PDF, DXF, DWG, IGS, STP, STEP, STL, etc. |

Nylon dyed 3D printing ensures rapid, reliable, and repeatable part creation—helping teams bring ideas to life with accuracy and flair.

Customization Options

Color (Min. order: 1,000 pieces)

Customized logo (Min. order: 1,000 pieces)

Customized packaging (Min. order: 1,000 pieces)

Graphic customization (Min. order: 1,000 pieces)