The world of 3D printed dragons, 3D printed toys, and 3D printed figures has rapidly gained popularity among both hobbyists and professionals. With the advent of accessible 3D printing technology, creating intricate, lifelike dragons has become a feasible and exciting pursuit. Whether the goal is to produce a collectible figure, a gaming piece, or an artistic sculpture, 3D printing opens the door to unlimited creative possibilities. This guide will explore the essential steps for crafting a 3D printed dragon, covering the design process, software tools, 3D printing materials, common challenges, and practical applications of these printed models.

Step-by-Step Guide to Crafting a 3D Printed Dragons from Concept to Final Product

Creating a 3D printed dragon involves multiple steps, from conceptualization to the final print. The process can be broken down into manageable phases, each requiring attention to detail and proper planning. Here is a basic step-by-step guide to crafting a 3D printed dragon:

1. Conceptualizing the Dragon Design

Before the 3D printed dragon can come to life, the first step is to define the dragon’s design. This involves deciding on aspects such as size, pose, and features (e.g., wings, scales, claws). It is essential to have a clear vision or reference images to guide the process. Artists often sketch their dragons to refine the design and solidify the proportions.

2. Choosing the Software for Design

Once the design is conceptualized, it’s time to translate that vision into a digital model using 3D modeling software. Popular choices for creating 3D printed toys and figures include:

- Blender: A free and open-source software, Blender is powerful for modeling, sculpting, and texturing. It allows for intricate detailing, making it ideal for complex designs like 3D printed dragons.

- ZBrush: Known for its high-resolution sculpting capabilities, ZBrush is widely used for detailed figures. It’s perfect for adding fine details to the dragon, such as textures for scales or facial features.

- Tinkercad: A beginner-friendly option, Tinkercad is a simple tool that works well for basic designs or for users new to 3D printing.

- Fusion 360: This tool is great for engineering-based designs and can be used to create dragons that require precision in their structural elements.

3. Refining the Model

After the basic structure is built, it’s important to add intricate details like textures for the dragon’s scales, wings, and claws. This is where skills in sculpting and texturing come into play. Attention to these small elements ensures that the 3D printed dragons will have a more realistic and appealing appearance when printed.

4. Preparing the Model for 3D Printing

Once the model is ready, the file must be prepared for 3D printing. The file format typically used is STL, which is compatible with most 3D printers. Before printing, it’s essential to check for errors like non-manifold edges or inverted faces that can prevent the model from being properly printed. Software tools like Meshmixer or Netfabb can help repair common issues in the model.

5. Printing the Dragon

After preparing the model, the next step is to set it up for printing. This requires selecting the appropriate settings in the printer’s slicing software. This software divides the 3D model into layers, providing the printer with the instructions to create the object layer by layer. The print settings will depend on factors like the size of the dragon, the resolution required, and the material chosen.

Software Tools and Skills Needed to Design a 3D Printed Dragon

Creating a 3D printed figure of a dragon requires a combination of creative and technical skills. Beyond the basic use of 3D modeling software, knowledge of the specific design requirements for 3D printing is essential. Here are some key tools and skills that will be helpful:

- Modeling and Sculpting: Proficiency in sculpting tools (e.g., ZBrush or Blender) allows for the creation of complex and detailed shapes. For 3D printed dragons, skills in modeling organic shapes like scales, wings, and facial features are critical.

- Texturing and Painting: While some 3D printed figures can be left unpainted, many people prefer to add color and texture. Texturing software like Substance Painter can be used to apply realistic textures to the digital model before printing.

- File Optimization: Ensuring that the 3D printed dragon is optimized for printing is crucial. This includes fixing any errors, ensuring proper wall thickness for durability, and minimizing the use of support structures.

Tips for Choosing the Right 3D Printer and Materials for Detailed 3D Printed Dragons

1. Choosing the Right 3D Printer

Selecting the appropriate 3D printer is a crucial step in creating a high-quality 3D printed dragon. For detailed models, resin printers (such as those using SLA or DLP technology) are often the best choice due to their ability to produce fine details. These printers provide high resolution and are ideal for models that require intricate textures like dragon scales.

Best Printer for making 3D Printed Dragons.

FDM printers (fused deposition modeling) are more accessible and affordable, but they are better suited for larger, less detailed models. If opting for an FDM printer, be sure to choose one with a high resolution (e.g., 0.1mm layer height) to capture finer details.

When crafting detailed 3D-printed dragons, selecting the right printer and materials is crucial for achieving exceptional results. For fine, intricate designs, resin printers like SLA or DLP provide unparalleled precision, capturing even the smallest features with stunning clarity.

The material choice also impacts the final look—resin prints are smooth and detailed, ideal for capturing the sharp contours of a dragon’s face, while PETG is a solid alternative for strength and flexibility. By pairing the right printer with the right material, you can ensure your 3D-printed dragon not only stands out for its detail but also endures the test of time and use.

2. Selecting the Right Material

The material chosen for the 3D printed figure will impact its durability and aesthetic qualities. Common materials for 3D printed models include:

- PLA: A popular, eco-friendly choice that is easy to print with. While it may lack the durability of other materials, PLA is perfect for prototypes or small-scale dragon models.

- ABS: More durable and heat-resistant, ABS is a great option for larger, more robust figures.

- Resin: Used in SLA and DLP printers, resin is ideal for high-detail prints and can create the intricate features found in 3D printed dragons. It’s perfect for smaller models or figures with fine details.

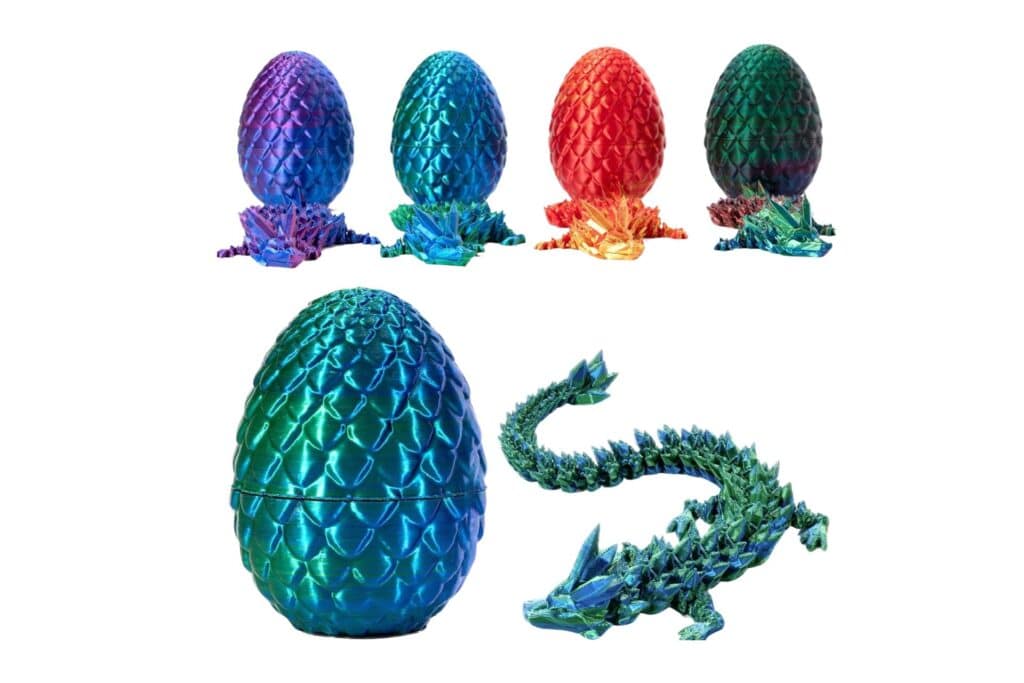

- Flexible Filaments: For a more unique dragon design, flexible filaments such as TPU can be used to create a dragon with movable parts or a more tactile feel.

Common Challenges in 3D Printing Dragons and How to Overcome Them

While the process of creating a 3D printed dragon can be highly rewarding, it comes with its set of challenges. Here are some common issues faced by creators and how to address them:

1. Print Failures

Sometimes, 3D printed figures don’t turn out as expected. Common causes include improper calibration, incorrect printer settings, or a misaligned model. Ensuring the printer is calibrated properly and using the right slicing settings can help prevent these issues.

2. Detail Loss

When printing large 3D printed dragons, there may be a loss of detail, especially if the print resolution is too low. Opting for a higher resolution print setting and using a resin printer can ensure that fine details like scales and textures are captured accurately.

3. Support Structures

Many dragon designs, especially those with wings or complex poses, may require support structures during printing. While support structures are essential, they can leave marks or damage the model. Learning how to position the model in the slicing software to minimize support structures can reduce the impact on the final print.

Practical Applications of 3D Printed Dragons for Hobbyists and Professionals

The applications of 3D printed dragons, 3D printed toys, and 3D printed figures are vast and varied. Here are some of the most common uses:

1. Collectibles

Many hobbyists and collectors create 3D printed dragons as part of their collection. These custom dragons can range from small figurines to large sculptures and are often highly detailed. Collectors value the ability to personalize their models, such as choosing specific poses or adding unique colors.

2. Gaming

In the gaming world, 3D printed figures are commonly used as miniatures in tabletop games. Players can create custom dragons that fit their campaign’s storyline or use them as models for characters in role-playing games. A 3D printed dragon can become a central piece in an epic battle scene.

3. Artistic Displays

Many artists use 3D printing to create detailed dragon sculptures for display in galleries or private collections. The ability to create large, detailed models allows artists to push the boundaries of their work, showcasing lifelike dragons with intricate designs.

4. Storytelling

Authors, filmmakers, and animators can use 3D printed dragons in their storytelling projects. Physical models of dragons can be used as reference material for animation or visual effects, helping to visualize the creatures in a tangible form before bringing them to life digitally.

Conclusion

Crafting a 3D printed dragon from concept to completion is a process that involves creativity, technical skills, and a knowledge of the printing technology and materials. With the right tools and techniques, hobbyists and professionals alike can bring these mythical creatures to life in ways that were once thought impossible. By following the steps outlined in this guide, anyone can embark on the journey to create their own stunning 3D printed dragons, 3D printed toys, or 3D printed figures, and explore the wide range of applications they can be used for.